AACE INTERVIEW: Minh Le Studio and the Le Family

Way way back during my childhood, I faced ongoing taunts, where people cruelly chanted a racist rhyme and mimicked eye-pulling, saying, "Chinese, Japanese, dirty knees." These hurtful experiences gave me two key realizations: I saw the cruelty in such actions and marveled at the simplistic view of diversity.

Not a Monolith

The Asian American community is incredibly diverse, with a history spanning over 150 years. Yet, despite this complexity, they are often unfairly perceived as a monolithic group burdened by stereotypes and misconceptions that mask their true identities. Recently, there has been a growing recognition of the importance of acknowledging and celebrating this diversity within the Asian American community. To truly grasp its richness and complexity, we must move past the long-standing biases and myths obscuring their unique identities.

During AAPI month in May, we have the yearly “call-outs” of the diverse tapestry of Asian cultures, we constantly strive to deepen everyone’s understanding of the subtle differences that make each culture special. At our AACE’s Potluck events for the AAPI cannabis community, I had the pleasure of meeting Duc, a constant bridge from our Asian roots to the cannabis community; at each event, Duc proudly displayed his exquisite Minh Le ceramic bongs.

The Minh Le story spans generations and continents, I invite you to join us on a journey from the heart of Vietnam to the heartland of America. - Ophelia Chong

Minh Le

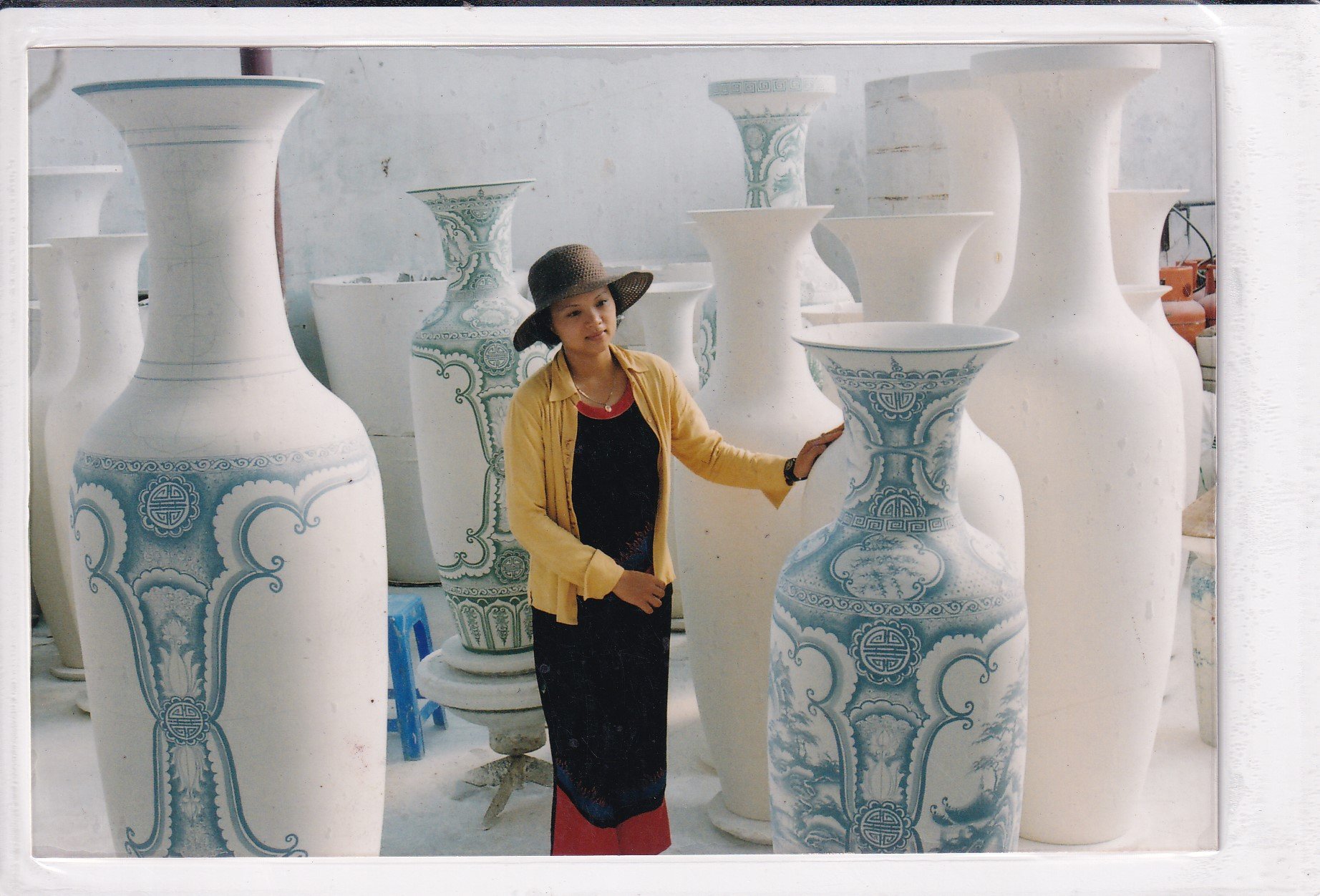

I'm Minh Le, and I'm currently 25 years old. I am from Bat Trang, a charming village nestled on the outskirts of Hanoi, Vietnam. Bat Trang has earned a remarkable reputation over the course of a millennium, dating back to the Lý Dynasty, as a renowned hub for ceramics, celebrated not only within Vietnam but also on the global stage.

My path leading up to Minh Le Studio

Although my family has a deep-rooted tradition in pottery, my decision to embark on a career in this art form was far from straightforward, contrary to what many might assume.

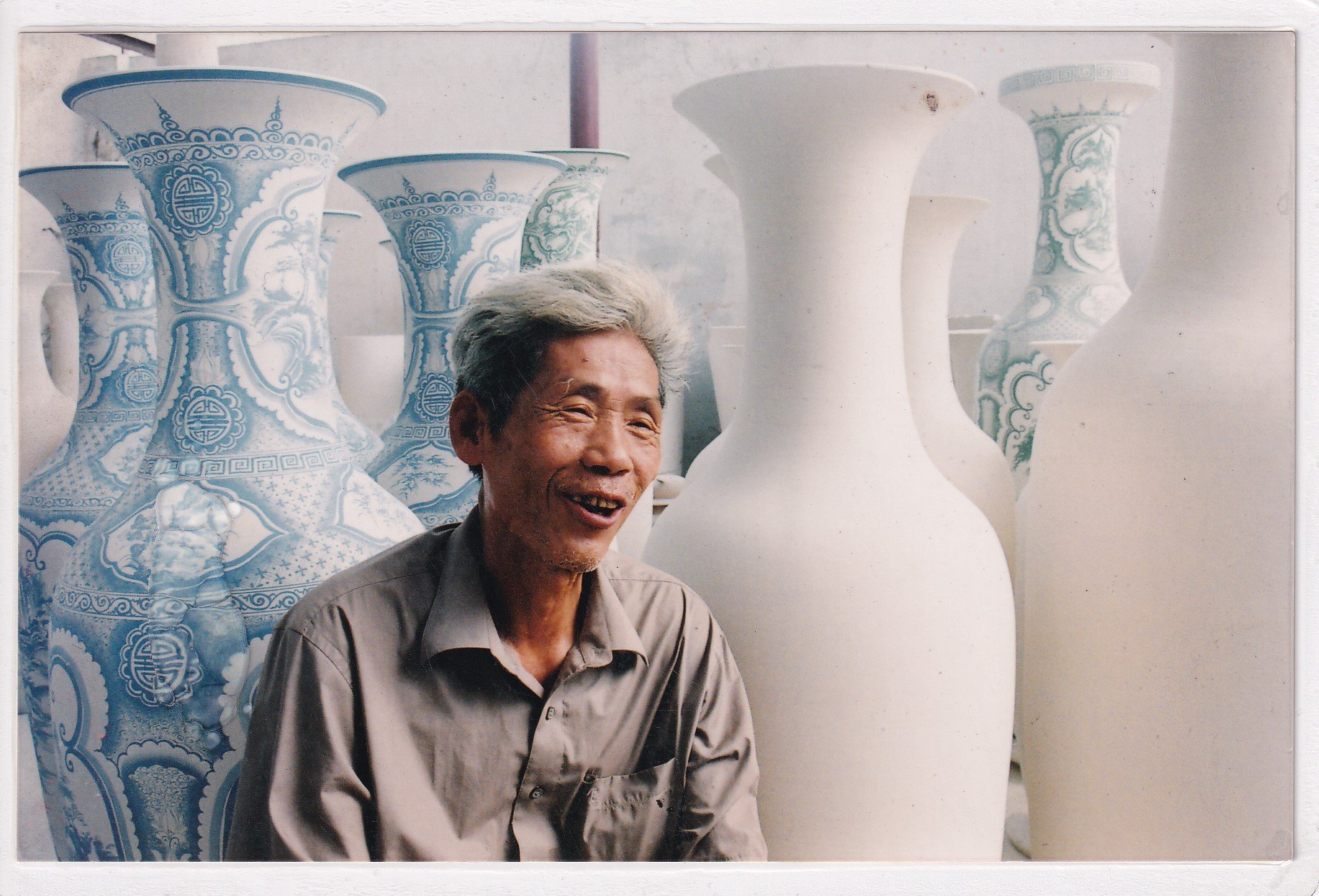

My father, a highly talented and skillful artisan, and my mother, a wise and courageous woman, once thrived in the world of ceramics. However, unforeseen events transpired, leading my family to cease pottery production a decade ago. At that time, I was too young to comprehend the profound significance of our family's ceramic legacy. I witnessed my parents' financial struggles despite their exceptional skills, and I naively believed that pursuing pottery was insufficient to provide for a family.

Following my high school graduation, I, like most of my peers, enrolled in college with the hope of attaining a degree that would secure a stable job and support my family. I gained admission to Hanoi University of Education, one of Vietnam's top universities, and pursued a major in Bio-Chemistry. Yet, it didn't resonate with me, so I made the difficult decision to drop out in pursuit of my true passion.

I embarked on a journey that took me to various cities and introduced me to a myriad of jobs, including bellman, hotel receptionist, waiter, security guard, programmer, salesman, carpenter, builder, mechanic, and more. While each occupation brought its own unique joys and lessons, I had not yet discovered my true calling.

After five years of exploration, diverse work experiences, and countless conversations with people from all walks of life, I began to recognize that my family's rich ceramic-making heritage was the source of my deepest pride. I found myself sharing stories of my father's extraordinary craftsmanship and my fervent

desire to carry on the family tradition someday. It was then that the realization struck me—my passion lay right here. It took years of searching to finally come to terms with this truth. I made a firm decision to pursue pottery.

In early 2021, I returned to my village in Bat Trang from Ho Chi Minh City, fully committed to the mission of revitalizing my family's business and picking up where my parents left off. With my newfound passion and clarity about my life's purpose, the journey became clear and uncomplicated. For me, there are no failures now—only stepping stones to success. Wherever I stumble, I rise again, and if I fall, I rise again and again until I achieve my goal. If I do not succeed, it simply means I have not reached the end of my journey.

Minh Le Studio represents the beginning of my pottery venture.

The Minh Le Studio Team

Throughout this journey, I have had the unwavering support of my older brother, Duc Le, and my wife, Ngan Dong, standing firmly by my side. We have each embraced specific roles to ensure the success of our venture: I oversee product design and production, my wife takes care of managing our social media presence and paperwork, and my brother handles our business operations in the United States.

Our Family’s History of Making Ceramics

In the year 1010, King Lý Thái Tổ made a momentous decision to designate Thăng Long, which is now known as Hà Nội, as the new capital of Vietnam. This pivotal move transformed the city and its surrounding regions into the political and economic epicenter of the nation. Consequently, it began to attract craftsmen from every corner of the country.

Around six centuries ago, a group of skilled potters hailing from Bồ Bát Village in Ninh Bình Province embarked on a migration to a place known as Bạch Thổ Phường, which translates to the "white clay area" and is now recognized as Bát Tràng. Their choice of Bát Tràng was driven by two primary considerations. First, the village's location was strategically ideal for trade. Situated adjacent to the Red River and less than 10 miles from the capital, Bát Tràng found itself conveniently positioned along the 714-mile-long river that originated in Yunnan Province, China. This river provided vital connections to numerous significant inland cities, including Thăng Long, ultimately linking them to the South China Sea. This critical trade route played a pivotal role in the prosperity of the village. Second, the potters discovered that Bát Tràng boasted an abundant supply of high-quality white clay, an essential ingredient for crafting ceramics.

Among the early potters who migrated to Bat Trang 600 years ago was my family ancestor, Mr. Lê Phúc Thái. He is credited with being the founder of the Lê Family of Bat Tràng. I am one of Mr. Lê Phúc Thái's 23rd generation descendants. While many of his descendants pursued various career paths, a significant number remained dedicated to the art of pottery. In my immediate family branch, the tradition of crafting ceramics has been upheld continuously for five generations.

Bat Trang Village

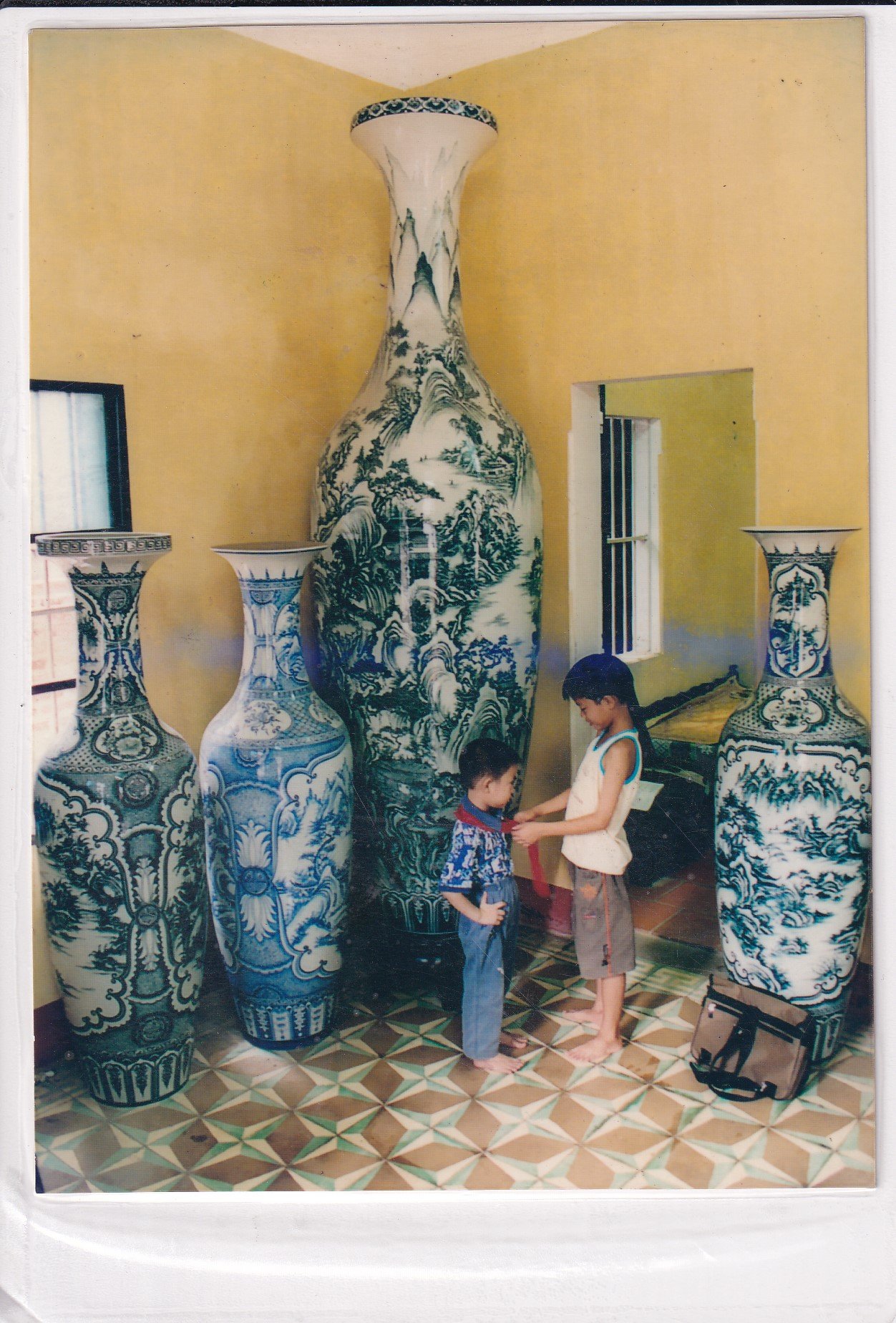

In the early days, given the high concentration of many skillful craftsman, Bat Trang quickly became well known and were the royalty products of choice. Regular customers include Prince, Princess and high ranking officials in the government. During 15th and 16th century, Bat Trang's pottery products were

often selected by the Vietnamese Emperors to be part of the tribute sent to Minh Dynasty (China). Currently, many of Bat Trang pottery pieces are showcased at the National Museum of Vietnam History.

In modern day, Bat Trang is the household name when it comes to pottery products known for its quality and the artistic value. It is one of the must-visit tourist destination when you go to Hanoi, Vietnam. This helped with my English skill as I grew up talking to tourist from all around the world.

Growing up in Bat Trang, everything felt perfectly 'normal' to me. I was surrounded by the constant sights and sounds of pottery-making. My parents were immersed in the craft, as were my cousins, aunts, uncles, neighbors, and even the parents of my friends. It seemed like almost everyone in our community was deeply involved in pottery. This was an era without the ubiquity of social media and easy internet access, which reinforced my belief that pottery-making was a universal way of life. As I've grown older, I've come to truly appreciate the exceptional fortune of being born into this rich and enduring pottery tradition.

Smoking Culture in Vietnam, My Family's Ceramic Making Tradition, and Cannabis: The Birth of Minh Le Studio:

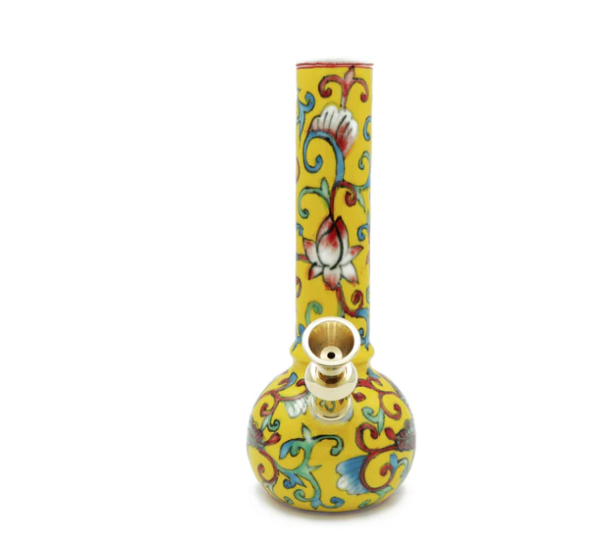

My overarching aspiration revolves around sharing the cultural gems of my homeland and the exquisite beauty of Vietnamese heritage with friends worldwide. While exploring various product ideas, I often encountered endeavors that seemed formidable and hyper-competitive.

Within Vietnam, the practice of smoking tobacco with water pipes crafted from bamboo, ceramic, and metal has deep roots, transcending societal strata for centuries. This custom is woven into the very fabric of Vietnamese culture, complete with folklore, tales, proverbs, and idioms venerating it. The prevalence of these water pipes is so remarkable that as you stroll through the streets of Hanoi, you'll find a bamboo pipe every ten meters.

A spark of inspiration suddenly illuminated my path. I recognized that the rich tradition of bong smoking in Vietnam, cultivated over centuries, could be harmoniously fused with our family's expertise in ceramic craftsmanship to yield a remarkable product. Moreover, the increasingly mainstream status of the cannabis industry in the United States and many other parts of the world revealed a distinct gap in the market for high-end ceramic bongs. It dawned on me that we could contribute something truly exceptional to this space.

Our Favorite:

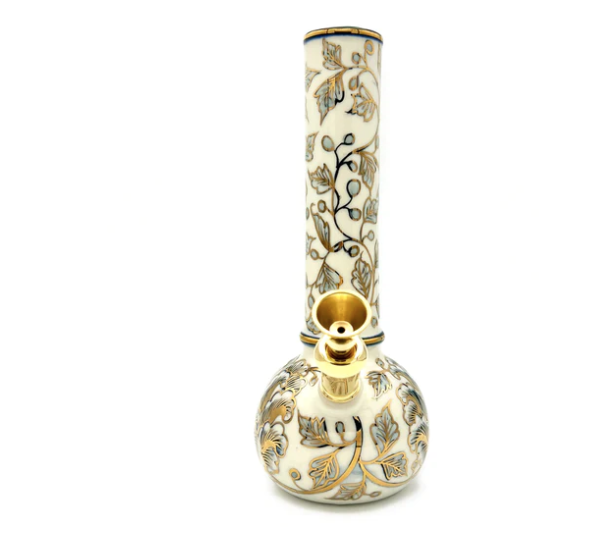

Blue Vines holds a special place in my heart as it represents our inaugural design, marking the inception of our creative journey. This timeless design also holds the distinction of earning our first accolade from Vogue magazine. The floral pattern adorning the bong features the artfully stylized Dixie rose, known as 'Phù Dung' in Vietnam, a symbol of alluring and opulent femininity.

Our meticulous application of the dot technique to embellish the leaf pattern is equally remarkable, with a rich historical lineage. Every stroke is painstakingly hand-applied, utilizing traditional brush painting techniques that trace their origins back to the Yuan Dynasty and the artisans of Arab ceramics, dating back to the 14th century.

The process:

The process of creating ceramics, especially in the context of Bat Trang, is an intricate and labor-intensive craft that involves numerous steps. Here's a detailed breakdown of the journey from design to the final product:

1, Design: The choice of a familiar bong shape was made to introduce ceramic bongs to consumers without overwhelming them with something entirely new. Future designs are in the works to bring innovative shapes while retaining the century-old knowledge to add a "wow" factor to the products.

2. Slip preparing

Sourcing Clay: In the early day, one of the reason our ancestors pick Bat Trang was for the high quality white clay. In the early of the 18th century, the source of clay here started to run out. We didn't move the whole village this time (that wouldn't be productive) and just transporting high quality white clay from the surrounding province. My family's favorite is the white clay from Trúc Thôn, Hải Dương Province. We have been sourcing clay from here for years now because of its pure white color, elasticity and extremely fine grain.

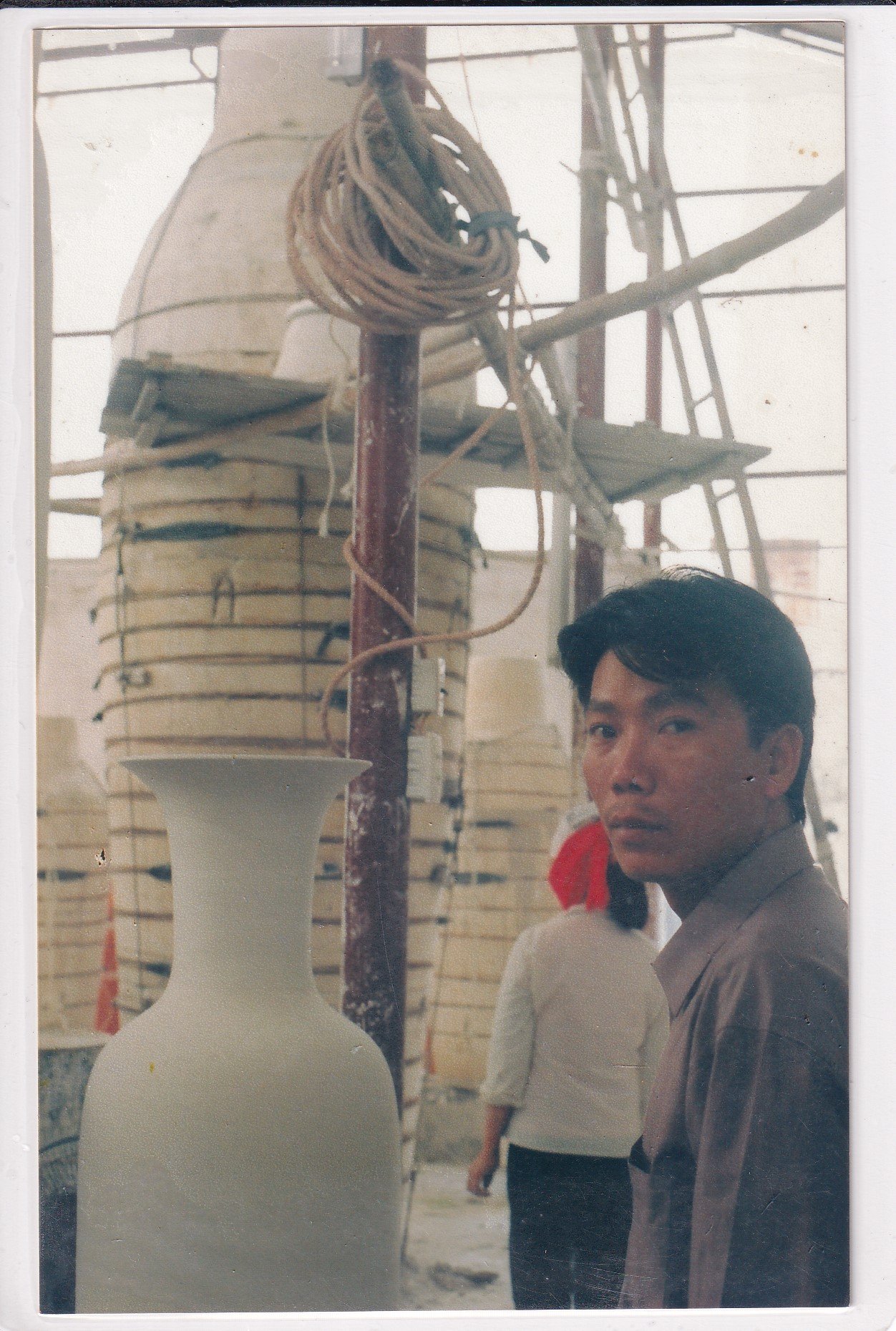

Slip preparing: Raw clay need to be mix with water and some additives to make it a slurry, which is suitable for slip casting. Slip can't be too dilute or too dense, it need to reach a specific density to make slip casting possible. But because of the instability of clay source, there is no fixed ratio of water and clay, we just can use experience to evaluate. My dad usually just put his finger tip in to the slip, if he say it okay, then it's okay.

3. Slip casting

Slip casting forming technique for pottery especially for shapes not easily made on a wheel. In this method, we poured slip into plaster molds and allowed to form a layer, the cast, on the inside walls of the molds. The longer we left slip in the mold, the thicker the cast is. We usually set the cast to be 6-10mm in thickness depend on the product. if it's thicker than that, a crack could form in the bottom of the piece while firing, If it's thinner than that, the piece could be crooked after firing. When the cast reach that specific thickness, we pour out all leftover slip and let the mold and the cast dry. Once the cast is leather-hard, it will begin to separate from the mold on its own. You must let the plaster molds dry out after 4 times of use. The plaster mold is now containing too much moisture and cannot continue slip casting, we have to dry it with heater in 3 hours to use it again.

4. Drying

Depend on thickness of the product and weather, it might take 2-15 days to remove moisture from clay. An experienced craftsman can evaluate the clay moisture level by the its color. The clay color gets lighter as moisture level drops. Additionally, the piece will weigh lighter because the clay will lose around 20% moisture if dried properly.

5. Trimming and cleaning up

After molding, my pieces usually have flash and the surface is not really smooth (the same while casting metal). We use a thin metal strip to clean the flash, use sponge and water to smooth the piece surface.

6. Bisque firing (700-800 Celsius degree)

There are two purpose of Bisque Firing

First is to transform greenware (unfired bone-dry clay) from its fragile state to a porous and durable state called ceramic for the second stage of firing. The process allows us to safely do decorative work, apply glazes on the piece without damaging or cracking it.

Second is to remove (burn) all organic compounds and water from clay. Make sure no air bubble appear on glaze surface on the glaze firing.

In bisque firing, we have to heat the clay slowly and cool it down slowly to avoid any crack. If rasing the temperature too fast, it will rapidly increase the internal pressure within the product causing it to break. We usually need 12 hours to reach 700 Celsius degrees and even longer to cool down.

7. Decorating (Drawing or engraving)

I typically collaborate with the local artisans on this step. Design patterns we use inspired by different culture at different point in time.

8. Glazing

Here in this step we coat the piece with a thin layer of liquefied glaze. The glazes in my village are very diverse and usually are family recipes passed down from many generations.

9. Glaze firing (1200-1280 C, based on the type of glaze)

Each glaze and clay type have a difference firing process, Western pottery usually have "cone" to determine firing process, which make it a little bit easier. But in Viet Nam, all ingredient, materials are inconsistent due to its natural origin of the resources. That's why it's a difficult step which will determine the success of the batch, only experienced craftsman like my dad, my uncle and my grandpa can do this. They have to control air flow, gas flow, adjust chimney, by checking the color of the fire and the sound of the gas burning. The process of firing can even must be adjusted depends on whether (air moisture, wind...). This step is usually get done during the night time because during the day we prepare and load the kiln. During summer, the weather gets really hot during the day and you don't want to work right next to the burning hot kiln. So night time is the preference for this step. Downside of this is you can't go to sleep. You must stay up to monitor the process. When I was a kid, I remember one time my dad got so tired and felt as sleep, that whole batch went out the window and my mom was not happy about it.

Memories

Before delving into the world of crafting bongs, one of the most indelible memories from my workshop days was witnessing my father's expertise during the Glaze Firing process. I can vividly recall the mesmerizing blue flames, the scorching intensity emanating from the kiln, and the enchanting 'pinging' (or 'singing,' 'tinkling,' or 'crackling') of the glaze as it cooled and took on its final form. It was a truly special moment that engaged all my senses, marking an unforgettable experience.

This magical transformation, where a nondescript chunk of clay metamorphosed into a vibrant and enduring work of art, felt like a profound act of creation. It was as though my father breathed life into his creations, bestowing upon them a soul and a new existence.

With the debut of my first bong batch, I found myself reliving this extraordinary moment. Witnessing my own pieces spring to life, I felt an unbreakable connection to my products, to my family, and to the

many generations of artisans who have contributed to the legacy of Bat Trang Village. For me, this marks the inception of everything I aspire to achieve in life.

Other Links:

About me Video (English Subtitle Available)